Wilson Benesch: How their six-figure speakers embody the history of a city and the future of sound

From its very first product – a record turntable built with the same cutting-edge technology as a racing car – Wilson Benesch sought to redefine sound. Here we explore how they combine method, materials and design mastery to create world-class systems that last a lifetime

For hundreds of years, Sheffield has rung out with the sound of industry and building; sitting in the natural crucible of the pennines and the confluence of five rivers, its name is synonymous with steel and the coal that powered it. And for the past 30 years, high-end audio company Wilson Benesch has been building a new sound for that city, and the world, making speakers and turntables that are an instantiation of that very spirit of innovation and industry.

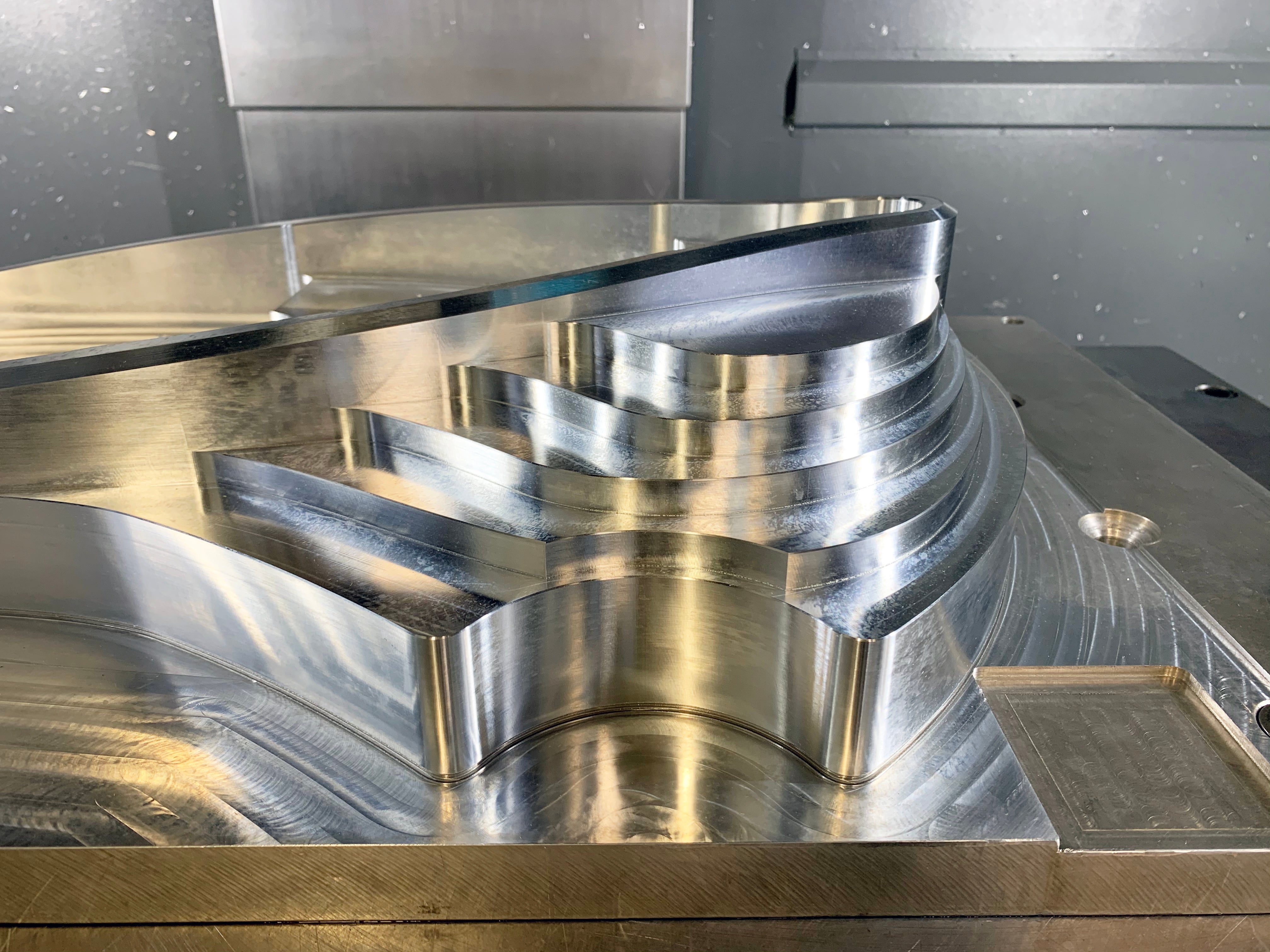

Sheffield’s industry has never gone away: its name is still etched in steel that finds a home across the world. The city actually produces more now than it did in its supposed golden age, though it’s more specialist and automated, the metal no longer clattering from a crucible and guided by human hands, but instead finely and precisely manufactured for global industry.

The modern Sheffield produces much else besides, putting that historic craftsmanship and internationally-renowned expertise to work building everything from vast plane engines to energy research at the very smallest, atomic scale.

It’s from that concurrent sense of history and innovation that Wilson Benesch emerged. The company was founded in 1989, on the strength of a proposal to the UK government to build one of the oldest pieces of technology in use today – a record turntable – from cutting-edge materials, carbon fibre composites more akin to a Formula One car.

The turntable arrived a year later, making good on that commitment to craftsmanship and refined design. At its centre was a material named Nomex, built like a honeycomb from carbon composites, combined with carbon fibre arms that tapered in a helix pattern, growing up the same way as a tree does, twisting in different directions, for the ultimate strength and stability.

Then, Wilson Benesch was one of four companies capable of making carbon fibre composite components this way. The others were Lotus Racing and two companies working for the Ministry of Defence; it might have looked like a record player, but was built with the care of a racing car or plane.

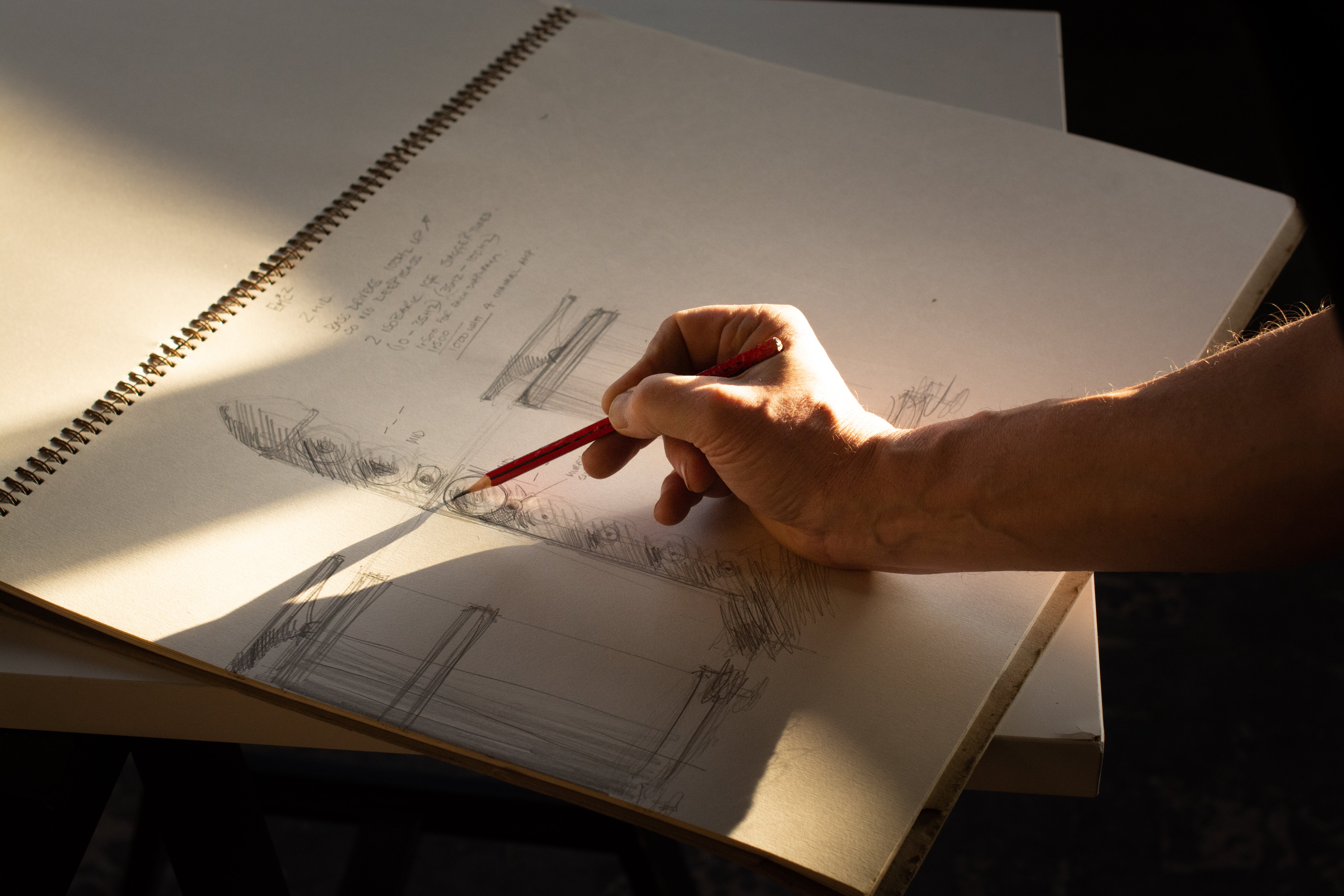

This set the stage for what Wilson Benesch does to this day, and the company is proud that while the materials used may be astonishingly futuristic, their products are developed via an iterative, thoughtful design process that aims to make them last forever.

All this innovative work happens at Wilson Benesch’s facility in Sheffield. Home to a staff of 20 who are among the world’s best engineers, their proximity means an idea can be hatched in the morning, drawn up on a computer in the afternoon, then 3D printed ready to iterate on soon after.

“We’re able to print these quite large structures and understand – by looking at how they fit together – that things that might appear one way on a screen are quite different once you have them in your hands,” says Luke Milnes, the son of the company’s founders Craig and Christina, who runs international sales and marketing. Rather than sending off designs to be manufactured elsewhere with no oversight, they are ideating and creating them all under the same roof.

This commitment to the thoughtful design and informed creation of products is visible in all of Wilson Benesch’s turntables and speakers. Just as they borrow from the advanced manufacturing process and materials of automotive and aerospace, the speakers sport similar looks too – all sweeping, curved sides that bounce off sound and draw the eye in.

The prices are comparable to those of a car, too, with entry level loudspeakers starting at £6,000, going up to the majestic Eminence reference speakers that cost £145,000. For that you get not only the elegant speakers and a part of that polished process, but a lifetime of great sound.

Before our chat, Luke has been helping out a customer in Singapore with a speaker built in 1991 – almost as old as him. It’s a reminder that these products are as far from the disposable gadgetry of much modern audio as they could possibly be. Each speaker is a little bit of history, being preserved to pass on to the next generation, a distillation of the whole history of a city, and a flavour of its future.

Much like Wilson Benesch, The Macallan also take great pride in high-quality British manufacturing, combining the finest ingredients and a sustainable production process to create a whisky of outstanding quality and distinctive character. The Macallan Double Cask range is available in The Whisky Exchange, The Whisky Shop, Waitrose and other premium retailers. Find out more at themacallan.com