Lithium breakthrough means key battery component can be extracted cheaply and sustainably from seawater

New method costs about 40 per cent less than current dominant method of lithium extraction and is cleaner, researchers claim

Scientists in the US have developed an “inexpensive” method to mine lithium from seawater, which they claim could lead to sustainable extraction of a mineral that is itself key to the global clean energy transition.

The global demand for lithium – used in the production of many types of batteries – has surged in recent years, driven by the popularity of electric vehicles. The metal’s production is estimated to go from about half a million metric tonnes in 2021 to about 4 million metric tonnes by 2030.

Traditionally, lithium is extracted from mined rocks, an expensive and energy-intensive process that requires the use of toxic chemicals.

More recently, miners have been producing lithium by evaporating concentrated salt lake brines which contain the metal. This method also involves high financial and environmental costs, however, and is dependent on specific climatic conditions and the availability of salt lakes.

Scientists have been looking for less expensive, more efficient and environmentally friendly lithium-extraction methods, and a Stanford University team now claims to have found one.

The new method of extracting lithium from brine is under 40 per cent that of today’s dominant extraction method, researchers said.

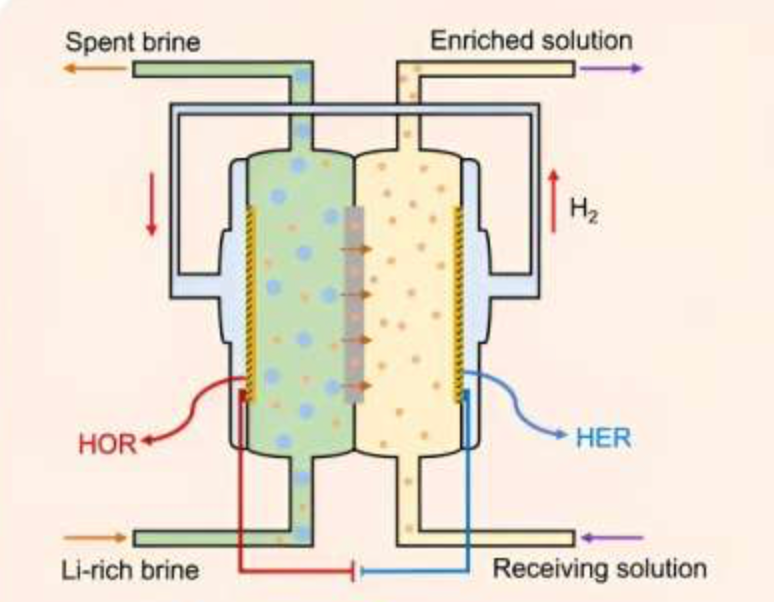

A process called redox-couple electrodialysis uses electricity to move lithium through a solid-state membrane from water with a low lithium concentration to a more concentrated, high-purity solution. Isolating lithium from this concentrated solution is then much easier, scientists said.

The new method reduces capital costs by eliminating the need for large-scale solar evaporation ponds and uses less than a tenth of the electricity needed in current brine extraction technology.

This method may also reduce the harsh ecological footprint of lithium production.

“The advantages displayed by our approach over conventional lithium extraction techniques enhance its feasibility in eco-friendly and cost-effective lithium production,” study lead author Rong Xu said.

“Eventually, we hope our method will significantly advance electrified transportation and the ability to store renewable energy.”

Experiments show that the new technology can extract lithium from wastewater from oil production and potentially from seawater, a process that is not commercially viable today.

“Direct lithium extraction techniques like ours have been in development for a while. The main contending technologies to date have significant drawbacks, like inability to operate continuously, high energetic costs,” said Ge Zhang, another author of the study.

“Our method seems to have none of these drawbacks.”

However, researchers added that some “stability problems” for the membrane when using seawater need to be tackled in further studies.

However, the technology performs well and efficiently even when scaled fourfold, Yi Cui, one of the researchers, said.

“This suggests that the method could be applied on an industrial scale, making it a viable alternative to current extraction technologies,” Yi said.

The new method could cost about $4,500 per tonne of battery-grade lithium carbonate compared to $9,100 per tonne when extracted from brine.

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments

Bookmark popover

Removed from bookmarks