First ever 3D-printed vertebra successfully implanted in 12-year-old cancer sufferer

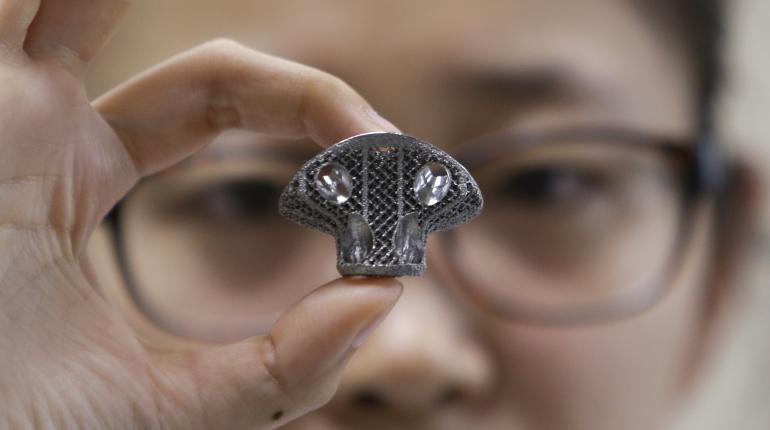

The replacement part was 3D printed from the same aluminium powder used in regular implants and has pores to let the bone grow into it

Your support helps us to tell the story

From reproductive rights to climate change to Big Tech, The Independent is on the ground when the story is developing. Whether it's investigating the financials of Elon Musk's pro-Trump PAC or producing our latest documentary, 'The A Word', which shines a light on the American women fighting for reproductive rights, we know how important it is to parse out the facts from the messaging.

At such a critical moment in US history, we need reporters on the ground. Your donation allows us to keep sending journalists to speak to both sides of the story.

The Independent is trusted by Americans across the entire political spectrum. And unlike many other quality news outlets, we choose not to lock Americans out of our reporting and analysis with paywalls. We believe quality journalism should be available to everyone, paid for by those who can afford it.

Your support makes all the difference.Chinese surgeons have successfully implanted a 3D-printed vertebra into the spine of a 12-year-old boy suffering from bone cancer.

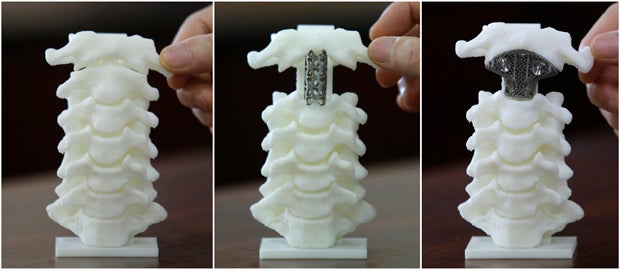

The surgery, which the doctors say was the first of its kind, took five hours in total, with the replacement vertebra constructed from titanium powder and incorporating tiny pores to allow the bone to grow into 3D-printed part.

The malignant tumour in the young boy’s spine was discovered after he was playing football and injured his neck while heading a ball.

Liu Zhongjun, the director of Peking’s Orthopaedics Department where the operation took place, explains that this unique design allowed doctors to avoid the screws and cements used in traditional implants that can sometimes detach years later.

"Using existing technology, the patient's head needs to be framed with pins after surgery," Liu explained to Reuters. "But with 3D printing technology, we can simulate the shape of the vertebra, which is much stronger and more convenient than traditional methods."

Custom 3D-printed bones and teeth are set to be one of the big areas of growth for the technology, with Cambridge research firm IDTechEx estimating that the market will be worth $6bn by 2025.

The technology has proved particularly useful in cases where the creation of an unusual body part is needed as quickly as possible.

For example, in March this year surgeons used 3D-printed windpipe splints to save the life of a 18-month-old boy, and in that some month the first ever 3D-printed skull was successfully implanted in a patient.

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments