How a Birmingham-based start-up is creating sustainable lithium battery packs

The founders of Aceleron speak to Zlata Rodionova about leaving their jobs with the idea to design a battery pack with a full circular economy approach

From powering our mobile phones and laptops to being a crucial component of electric vehicles, lithium-ion batteries are increasingly becoming an essential part of life.

However, as the world’s lithium-ion production capacity increases fuelled in part by a growing demand for “EVs”, questions remain about the batteries’ environmental impact.

Most lithium-ion batteries for renewable energy and electric vehicles are not designed to be maintained. If one of their components breaks down, the whole pack stops working which means that they cannot be repaired or easily recycled, leaving a waste problem in their wake.

This is where Aceleron comes in. The Birmingham start-up, founded in 2016 by Carlton Cummins and Amrit Chandan, uses new technology to create sustainable lithium battery packs.

Amrit, who holds a Phd in fuel-cells technology, met mechanical engineer Carlton while working in a low-carbon vehicle consultancy.

He tells The Independent: “Aceleron really started out as a lunchtime conversation. We got talking about the challenges that we saw coming with electric vehicles taking the market by storm.

“We decided that this, coupled with the need for battery storage as renewables take off, was a big enough challenge for us to take on to solve.”

The pair left their respective jobs to found Aceleron with the idea to design a battery pack which is made with a full circular-economy approach.

In addition to accelerating the transition to green energy usage, their underlying mission is to positively impact the lives of people in developing regions

Carlton explains: “The interesting challenge with the lithium-ion battery is not so much to do with the lithium-ion technology itself but how we make batteries. We weld things together via permanent assembly methods that reduce the cost but made for linear production.

“The idea is that you make it, use it and it gets disposed. It kind of works with smaller devices but scaled up it begs the question: how should we use batteries today?

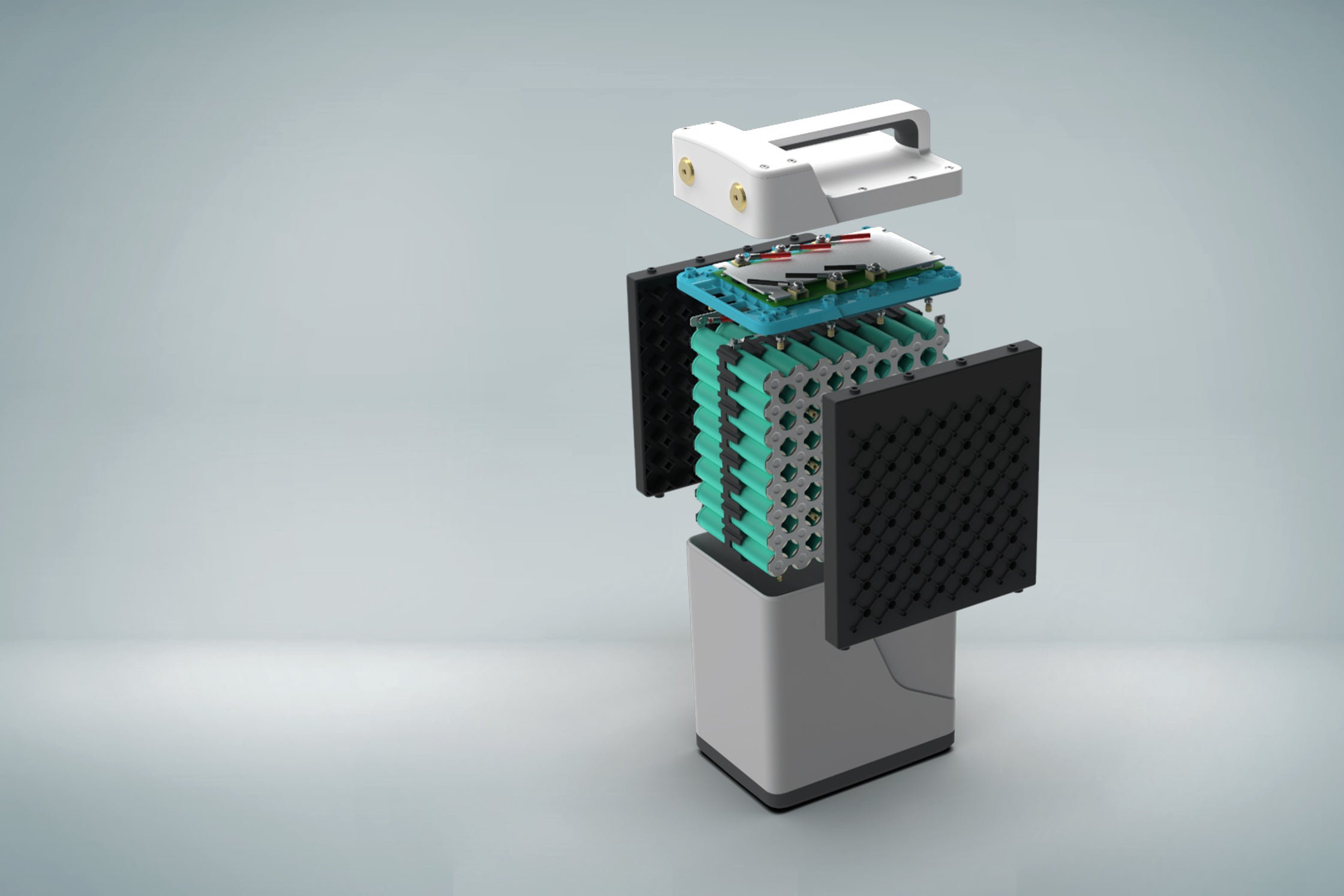

“A lot of what Aceleron has been focused on is changing the way we make it. Our batteries are designed to be repaired, repurposed and upgraded.”

What started as a simple conversation is now a 30-strong company spread across the UK and Kenya, selling different battery packs of various voltages and sizes used in vehicles but also sold for residential and consumer use.

Last year, the company secured £2m investment: £1.45m from BGF, the UK’s most active investor, and the remainder from existing investor Mercia Asset Management.

Amrit and Carlton, who are both recipients of the Forbes 30 Under 30 award in science and healthcare, hope the investment will allow them to scale the production of their battery technology and expand their company’s reach to global markets.

In addition to accelerating the transition to green energy use, their underlying mission is to positively impact developing regions.

“Carlton came from the Caribbean and my family originates in India, so it was very important for to us to give back for the opportunities that we’ve been fortunate to have,” Amrit says.

Through a partnership with the Shell Foundation, supported by the Foreign, Commonwealth & Development Office, Aceleron was able to bring its technology to Kenya where the company’s batteries were fitted in homes to power televisions, fridges and lights, often for the first time.

Amrit says: “Children in Kenya are no different from children in the UK. You give them access to electricity and the first thing they do is switch on the TV to see what’s on. They don’t care what is powering it, all they care about is how they can use it and how it impacts their lives. We all need energy and energy security is directly linked to the development level of some regions of the world.

“Schoolchildren in rural Kenya will also use kerosene lamps to do their homework at night and harm themselves by breathing toxic fumes. Being able to provide access to clean energy and solve this issue is really important to us.”

Although the company is revenue-generating today, Amrit and Carlton admit they have faced challenges along the way.

In addition to sourcing funding to support their supply chain, the founders had to overcome dogma around how batteries are made. They both feel grateful to have found a team that stuck by them through the process.

Nobody wants to throw things away, we’ll often do it because there’s no other option, not because it’s our preferred way to do so

Carlton said: “Finding a new way to make something is one challenge, finding a supply chain for it is another one, convincing people that this is a good idea is an additional challenge. So getting the team that will stick by it is a definitely a blessing.

“People perceive that the only way to do something is the way they’ve always done it. There’s an assumption that the only way to make batteries is this permanent assembly method that we’ve used since the nineties.

“We’ve demonstrated that there’s a different way to do that technically but it’s taken a while for people to embrace the reality that there’s a new normal that is possible.

“We would also argue that it’s a necessary new normal because we can’t afford to continue making things that can’t be repaired when batteries are becoming so ubiquitous.”

The Covid-19 pandemic has also given people around the globe the opportunity to reflect on what they would like their world to be and Aceleron’s founders argue it has demonstrated that better business models can be created.

“It has been useful for companies like ours to demonstrate that there is a new way to do things that can be commercially and environmentally attractive and good for the society,” Carlton says, before adding, “nobody wants to throw things away, we’ll often do it because there’s no other option, not because it’s our preferred way to do so”.

Aceleron is now preparing for a new product launch while looking to expand the humanitarian side of the business, including how their technology could be used in refugee camps.

Read More:

Carlton says: “It’s our first flagship-style of product that really demonstrates what happens when you built something from the ground up. It’s designed to replace lead-acid batteries. In developed markets these batteries can be heavy and cumbersome, sometimes they end up in the wrong places when it comes to waste management. Whereas in developing markets they have that nasty bugbear of causing lead poising as people recycle them inappropriately.

“We’re really excited having come up with a product which uses new technology lithium-ion batteries to mitigate these issues and it’s designed to be future-proof because it can be serviced and upgraded. It also has a universal usability as it can go into luxury yachts but also small homes and villages. We’re very excited to see how it will be embraced by the world.”

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments

Bookmark popover

Removed from bookmarks