RAF jets fly with parts produced on 3D printers

Your support helps us to tell the story

From reproductive rights to climate change to Big Tech, The Independent is on the ground when the story is developing. Whether it's investigating the financials of Elon Musk's pro-Trump PAC or producing our latest documentary, 'The A Word', which shines a light on the American women fighting for reproductive rights, we know how important it is to parse out the facts from the messaging.

At such a critical moment in US history, we need reporters on the ground. Your donation allows us to keep sending journalists to speak to both sides of the story.

The Independent is trusted by Americans across the entire political spectrum. And unlike many other quality news outlets, we choose not to lock Americans out of our reporting and analysis with paywalls. We believe quality journalism should be available to everyone, paid for by those who can afford it.

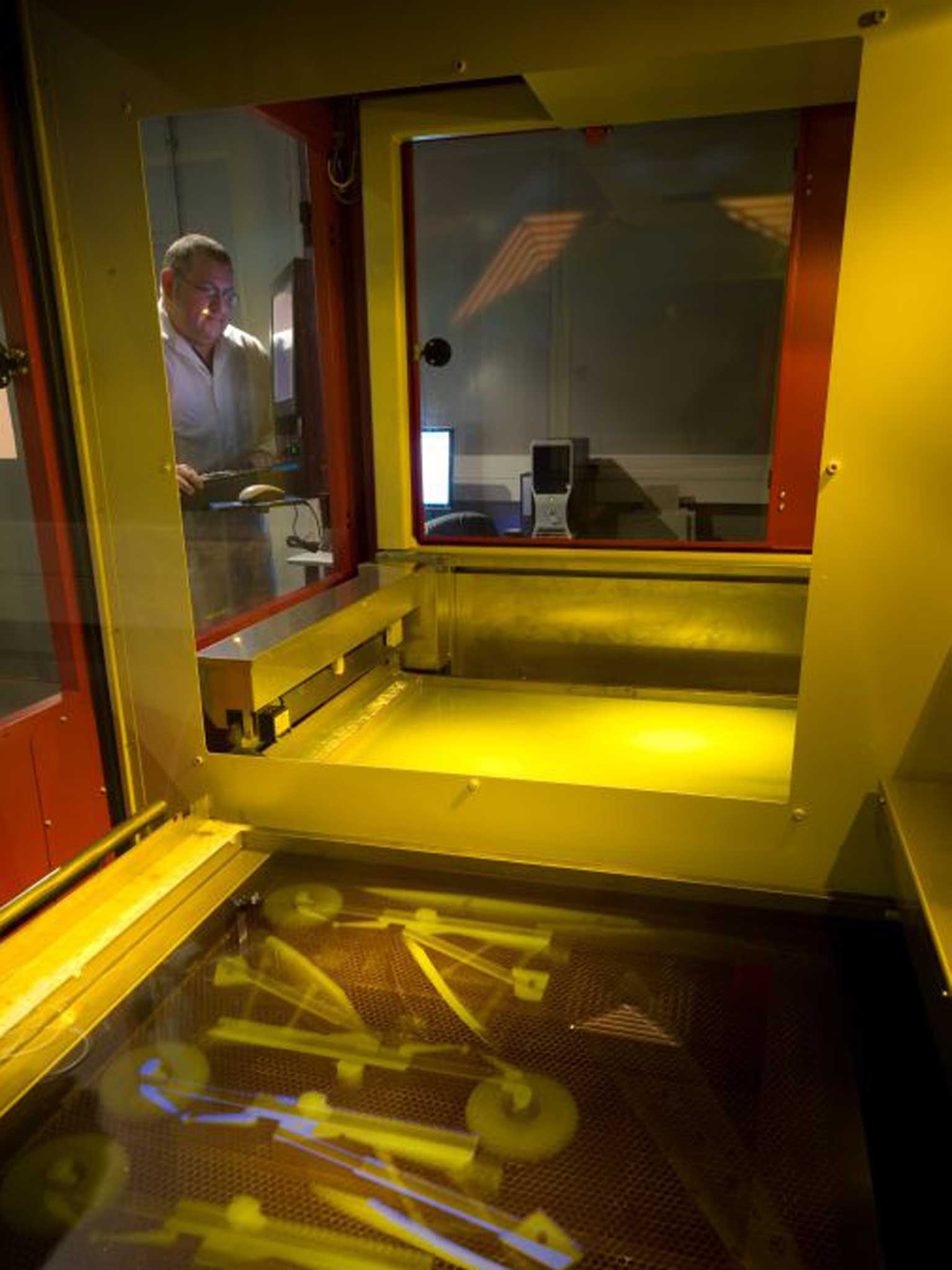

Your support makes all the difference.UK fighter jets have flown for the first time with parts made using 3D printing technology.

BAE Systems said the metal components were successfully used on board Tornado aircraft which flew from the defence firm's airfield at Warton, Lancashire late last month.

The company said its engineers are using 3D technology to design and produce parts which could cut the Royal Air Force's maintenance and service bill by over £1.2 million over the next four years.

BAE Systems is working at RAF Marham, Norfolk to engineer ready-made parts for four squadrons of Tornado GR4 aircraft, including protective covers for cockpit radios and guards for power take-off shafts. Some of the parts cost less than £100.

Mike Murray, head of airframe integration at BAE Systems, said: "You are suddenly not fixed in terms of where you have to manufacture these things. You can manufacture the products at whatever base you want, providing you can get a machine there, which means you can also start to support other platforms such as ships and aircraft carriers.

"And if it's feasible to get machines out on the front line, it also gives improved capability where we wouldn't traditionally have any manufacturing support."

PA

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments