Stonehenge's most intricate archaeological finds were 'probably made by children'

Gold micro-working is probably too detailed for adults

Your support helps us to tell the story

From reproductive rights to climate change to Big Tech, The Independent is on the ground when the story is developing. Whether it's investigating the financials of Elon Musk's pro-Trump PAC or producing our latest documentary, 'The A Word', which shines a light on the American women fighting for reproductive rights, we know how important it is to parse out the facts from the messaging.

At such a critical moment in US history, we need reporters on the ground. Your donation allows us to keep sending journalists to speak to both sides of the story.

The Independent is trusted by Americans across the entire political spectrum. And unlike many other quality news outlets, we choose not to lock Americans out of our reporting and analysis with paywalls. We believe quality journalism should be available to everyone, paid for by those who can afford it.

Your support makes all the difference.Some of the most high status pieces of prehistoric ‘bling’, prized by Stonehenge’s Bronze Age social elite, are likely to have been made by children, according to new research.

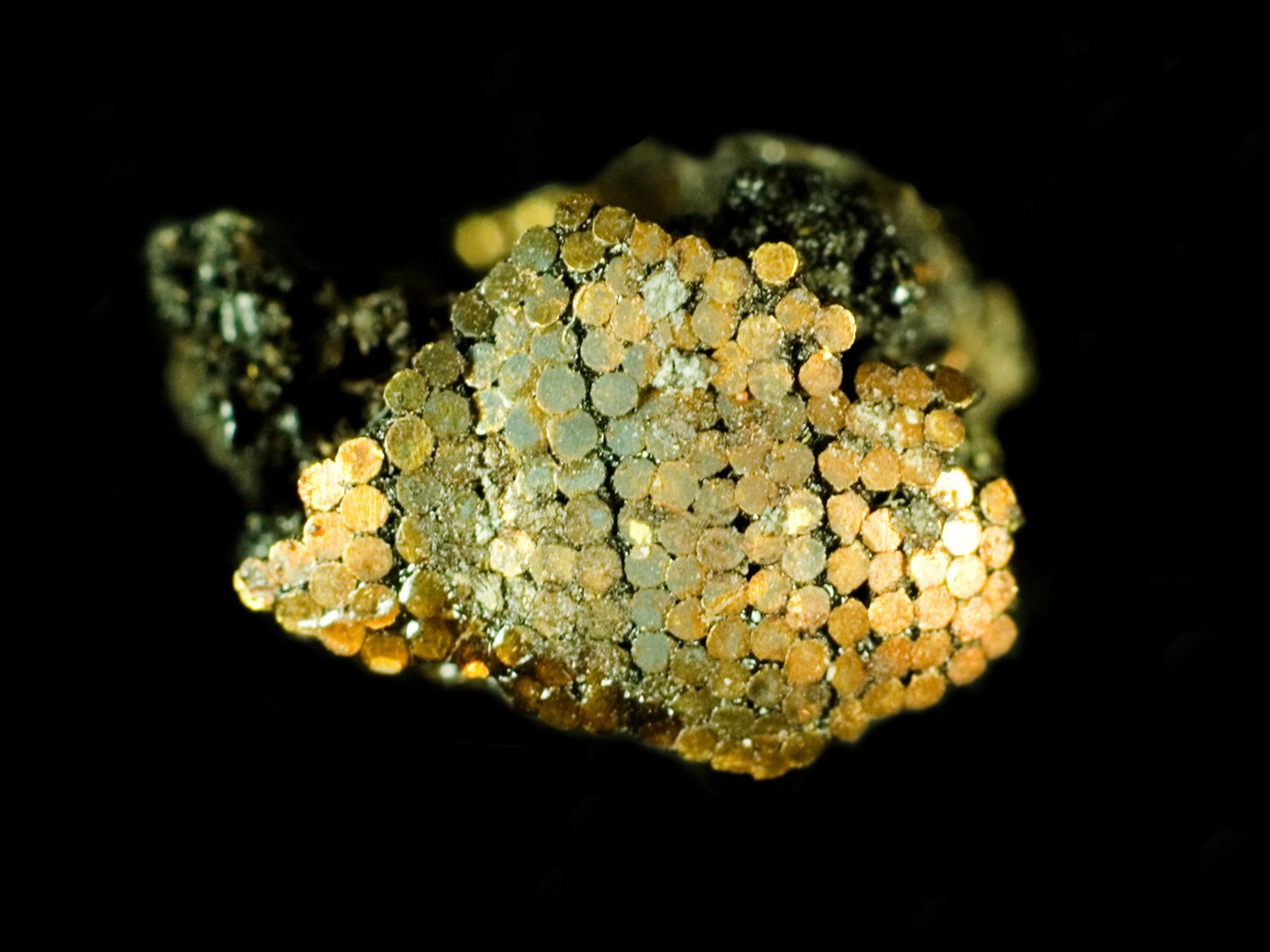

An analysis of objects, found near the ancient stone circle, shows that the ultra-fine craftwork involved such tiny components that only children or myopic (short-sighted) adults could have made them.

The research into the human eyesight optics of micro-gold-working in the Bronze Age has considerable implications for more fully understanding the nature of society in Western Europe some 4000 years ago.

“The very finest gold work involved the making and positioning of literally tens of thousands of tiny individually-made components, each around a millimetre long and around a fifth of a millimetre wide,” said David Dawson, Director of the Wiltshire Museum in Devizes where the world’s finest prehistoric micro-gold working achievements are on display as part of a major permanent exhibition of Bronze Age gold treasures.

“The implication is that there would almost certainly have been a small section of the Bronze Age artisan class who, often as a result of their childhood work, were myopic for their adult life. They would therefore have been unable to do any other work apart from the making of tiny artefacts and would have had to be supported by the community at large,” he said.

The Stonehenge area object with the largest number of ultra-small gold components is a dagger made in around 1900 BC – and now on display in Devizes’ Wiltshire Museum. Crafted more than 1100 years before the invention of the first magnifying glass, the dagger’s 12 centimetre long handle was adorned with up to 140,000 tiny gold studs – each around a millimetre long and around 0.2 of a millimetre in diameter. Even the heads of each stud are just a third of a millimetre wide. They were set, with great manual dexterity and remarkable skill, into the surface of the wooden dagger handle - with more than a thousand studs neatly embedded in each square centimetre.

The prehistoric gold micro-working process appears to have had at least four stages. First, Bronze Age craftsmen manufactured lengths of extremely fine gold wire, almost as fine as a human hair. Then they flattened the end of a piece of wire to create the first stud-head – and cut the wire with a very sharp flint or obsidian razor a mere millimetre below the head. This delicate procedure was then repeated literarily tens of thousands of times – to decorate just one dagger handle! Next, a tiny bronze awl with an extremely fine point was used to create minute holes in the dagger handle in which to position the studs. Then a thin layer of tree resin was rubbed over the surface as an adhesive to keep the studs in place.

Each stud was then carefully placed into its miniscule hole – probably with the help of a very fine pair of bone or wooden tweezers, because the studs are too small to have been placed in position directly by the artisan’s fingers.

“We estimate that the entire operation – wire manufacture, stud-making, hole-making, resin pasting and stud positioning – would have taken at least 2500 hours to complete,” said David Dawson.

The dagger – and another probably less decorated similar weapon found with it – are believed to be the only such ultra-fine micro-worked artefacts to have survived from the prehistoric period anywhere in the world. But the high level of skill involved suggests that it was not a one-off creation, but was instead probably a product of a wider micro-gold-working tradition in at least part of Bronze Age western Europe. It is likely that the tradition was centred in Brittany in what is now western France.

It is also conceivable that Bronze Age craftsmen used comparable micro-working skills to create ultra-fine textiles.

The gold-studded daggers were discovered in 1808 inside Bush Barrow, a substantial Bronze Age burial mound, located almost a thousand metres from Stonehenge. However, it is only now that the eyesight and other human implications of its manufacture have been examined in detail.

By their early 20s, many would have perceived people and objects more than a metre away as just blurred impressions. In a world without spectacles, it would have been impossible for them to operate normally within society – and they would have had no alternative but to continue with and develop their micro-working crafts. But, ironically, that would have made them valuable economic assets – despite their poor sight.

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments