The true cost of Britain’s addiction to factory-farmed chicken

Of the 1 billion chickens raised in the UK each year, 95% are factory farmed. Chicken is the country’s most popular meat and these massive sheds are why it’s so cheap, but what are the real costs, asks Alison Caffyn

The first time I encountered an intensive “chicken shed” up close I was taken aback by just how massive it was – the huge industrial-looking metal clad building was well over 100 metres long by 25 metres wide. And there wasn’t just one, there were seven of these colossal sheds, the sun glinting off their roofs and adjacent clusters of tall silos. A constant hum emanated from them and periodically a strange clattering sound, possibly of grain being sprayed automatically from a silo into a shed.

There was a large, immaculately clean concrete yard and an almost uncanny lack of human activity. Finally, overwhelmingly, was the all-pervading smell. The malty, almost sweetish odour became increasingly unpleasant as I stood to take in the scene, making me feel slightly sick.

The distinctive stink followed me as I continued down the footpath. I began to develop a headache. I felt jumpy despite being on a public right of way – should I be this close to what I knew was an intensive poultry unit? Were there biosecurity risks?

And when the path veered close to the building I began to actually hear the birds inside. That triggered other emotions. I knew that the chickens were on a life trajectory of a mere six weeks (eight weeks for “slow grow birds”) before they would be loaded onto lorries to be taken to the processing factory.

Later, several farmers showed me round their sheds. Inside one, I stood rather stunned at the sheer scale of the building stretching in front of me and the 45,000 chickens crowded into the space. They pecked at plastic feeders or the occasional small bale of hay providing “environmental enrichment”.

This is how 95 per cent of the 1 billion chickens raised in the UK each year are grown: chicken is the country’s most popular meat and these massive sheds are why it’s so cheap.

The premises which produce much of the UK’s meat are relatively hidden from view. Not only do most people not want to think about how meat is raised, it is in the interests of the intensive livestock industry to keep a low profile. Many meat eaters understandably tend to avoid watching documentaries and reading about the horrors of factory farming. Out of sight, out of mind. The meat industry knows this too, and tries hard to keep the realities of the conditions that industrially farmed animals are kept in divorced from the product people buy in supermarkets.

Going into poultry is an attractive proposition for farmers. Consistently the most profitable UK agricultural sector, poultry provides a steady income and is not dependent on subsidy

But this article isn’t about animal welfare realities. It’s about how the poultry industry has managed to keep a low profile while undergoing a massive expansion to supply all the supermarkets and fast food chains. There has been an intensive poultry industry in the UK for over 60 years, but it has been upscaling in recent decades, becoming more like North America’s mega farms.

For the last four years, I have been investigating how intensive poultry units have been allowed to multiply across certain parts of the UK. I have discovered that the poultry industry has taken advantage of weak regulatory and planning regimes in order to expand what is a very profitable business. I have traced how local people have become increasingly angry about the myriad impacts they face from the intensive chicken sheds – and how they have mobilised to fight the industry’s expansion.

I live in Ludlow, Shropshire, close to the Herefordshire border. These two counties are at the heart of the UK’s chicken industry. My attention was first drawn to the issue in 2014, when I began to notice frequent articles and angry letters in my local papers, the Hereford Times and the Shropshire Star. The headlines read things like: “Stench from broiler units is inescapable”; “Protesters mass to fight ‘terrible’ chicken farm”.

Campaigns against several planning applications for what are known in the business as intensive poultry units (IPUs) had been launched in the Shropshire Hills (an Area of Outstanding Natural Beauty) and scenic and tranquil parts of Herefordshire. A significant controversy had kicked off. Some planning applications had hundreds of letters submitted objecting to the proposals. I wanted to know what had prompted the levels of outrage in an area where there has been commercial chicken farming since the 1950s, and set about researching the issue for my PhD.

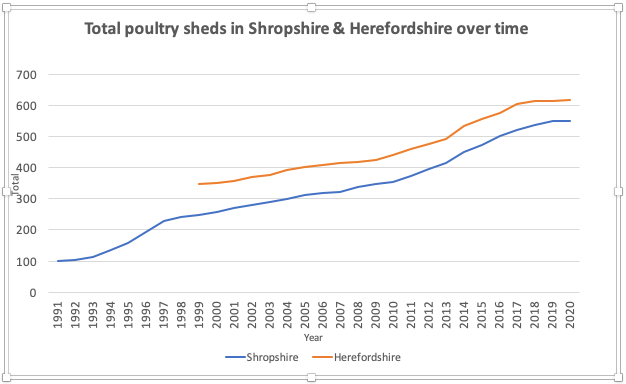

When I began to trace the pattern of planning applications across Herefordshire and Shropshire, trawling through the records for each county, it became clear that the industry had expanded steadily over the 1990s and 2000s, with more and more farms investing in poultry and IPUs becoming progressively bigger. Where the average broiler (meat chicken) shed held 25,000 birds in 1990 and 40,000 birds in the 2000s, the new applications were for sheds to hold 50,000-55,000 birds at a time. By 2010 there were at least 800 chicken sheds, for meat and also many for eggs, across the two counties, which I estimate to be around 20 per cent of the UK total.

I found there had been a sudden surge in applications in the early 2010s, partly as a result of supermarkets wanting to source more chicken from the UK in the wake of the horsemeat scandal. In 2013-14 for example, the huge chicken processing plants in Hereford, run by multinational Cargill, took on a new contract with Tesco to provide an additional million chickens a week. This required a further 90 chicken sheds within an hour’s drive of the plants and many farmers were keen to become suppliers.

I started to interview as many people as I could: farmers, planners, local authority and environmental agency staff, councillors, objectors, campaigners and other local businesses; and began to understand why the controversy had erupted.

Going into poultry is an attractive proposition for farmers. Consistently the most profitable UK agricultural sector, poultry provides a steady income and is not dependent on subsidy, unlike most UK farming. The farmers I spoke to wanted the “certainty” that a contract with a poultry processor gave them. Several wanted to expand and create a job for a member of the next generation and to make the farm more resilient, particularly given the uncertainties over Brexit.

Expanding into poultry is a big investment; in the region of £2.5m for a four-shed broiler unit. But I was told farms can pay off their investment within 10-15 years and more quickly if they also installed renewable energy systems such as solar, biomass and anaerobic digestion (AD) units, all of which receive government subsidies.

But once the system is up and running, it doesn’t require much physical effort (at least compared to traditional farming methods). The vast majority of chicken farming in the UK has joined other forms of “precision farming” that uses smart technology within an integrated system owned and organised by a processing company.

The campaign group reached out to local experts to learn more about the impacts. They learned how the ammonia gas from the chicken faeces is pumped out of sheds into the air and damages local habitats

Day-old chicks are delivered from the hatchery. The processor (such as Cargill) provides the feed and sends in “catching gangs” and lorries to pick up the birds after six weeks. The farmer never actually owns the birds but carries the risk if more than the normal 5 per cent die before reaching the processing plant.

The farmer is able to monitor the shed temperature, humidity and check on feed, water and so on on their computer or phone. All it requires is for someone to walk through each shed daily picking up the dead and sick birds. This means the intensive chicken production provides only about 1.5 workers on each average farm of four to six sheds (although some of the operations have ten or 15 sheds). A poultry farmer told me that these larger businesses can make in the region of £1m profit a year.

The justifications for IPUs I heard at planning committee meetings mainly revolved around the need for affordable, healthy protein to feed the nation. The UK is about 75 per cent self-sufficient in poultry (according to figures published by the Agriculture and Horticulture Development Board in 2018, although little recent data has been made available). Emphasis was placed on how raising chicken in the UK is better in terms of food miles and animal welfare as the UK has higher welfare regulations than in many parts of the world.

Farmers applying for planning permission for new units stressed the supply chain and economic benefits as well as the jobs in the processing factory. They accused objectors of being incomers to the area; “NIMBYs” or “down-from-Londoners” who didn’t understand the realities of modern farming and who had unrealistic, idyllic ideas of what rural life is like.

They denied the IPUs would cause any environmental problems, saying that they had to meet environmental permit standards and that the Environment Agency would address any inadvertent pollution. They denied that IPUs smell and ridiculed those who complain about agricultural smells or noises in rural areas.

It is true that these intensive chicken units vary considerably. There is a huge difference between the larger sites, some owned directly by the processing company, where there may be 10 or more sheds and very little other farming activities, and at the other extreme small farms that have diversified into free range eggs because their beef or sheep enterprise has struggled to make a profit. But both types can be controversial.

(Most UK eggs are also produced in intensive units; standard free-range units house 16,000 or 32,000 hens in systems where the birds have theoretical access to the outdoors, while in contrast conventional systems may house millions of hens).

The surge in applications to supply Cargill in 2014 included some in particularly scenic and biodiverse environments. This created a PR disaster. Local people who had always been largely tolerant of agricultural activities felt the expansion of the poultry industry had become “something other”, as one officer described. Resistance crystallised and a range of local people began to mobilise to fight the proliferation of further poultry units.

So were these objectors really just retired NIMBYs and ignorant townies?

I interviewed numerous people who objected to the IPU proposals and followed one group of campaigners that formed in a small, historic village not far from my home. The farming family who own much of the land around the village was proposing to build a new poultry site, close to residents’ houses. I attended the campaign group’s meetings in the back room of the village pub.

I listened to them discussing what was meant by the scientific terminology used in the various odour, noise, ecology and visual impact assessments. They became increasingly expert in understanding the planning process and the technical information used. I heard their frustrated complaints about the unfairness of the process, the profits made by the interconnected farming families and the influence such landowners had on the parish council and local planning committee.

There was a sense of injustice that one business could inflict such change on the local area and community. Unlike with some invasive developments such as wind turbines, electricity pylons or housing developments, there are no financial payback mechanisms which would fund community projects or facilities in recompense. I regularly heard objectors mention the fact that farmers do not even pay business rates on their poultry operations as they are deemed agricultural developments.

The campaign group reached out to local experts to learn more about the impacts. They learned how the ammonia gas from the chicken faeces is pumped out of sheds into the air and damages local habitats and ancient woodland, and how excess manure spreading has been found to cause illegal levels of pollution in local rivers. I joined the group on a visit to a nearby Site of Special Scientific Interest to see breathtaking swards of orchids and other rare plants in stunning wildflower meadows – also vulnerable to cumulative ammonia emissions.

What this all brings home is the wildly unnatural price of chicken in the UK. Why can you buy a whole chicken at Tesco for under £3?

This group was typical of the objectors I met: a mix of some people who had moved to the area to work or retire, alongside long-time residents. Some were older but there were many middle-aged people, some professionals who developed the expertise in planning processes but also many others who supplied local knowledge, contacts and who simply cared about what was changing in their local countryside and how it impacted on their families and friends.

I also met several farmers who objected to intensive poultry. One told a friend of mine, while contemplating his neighbour’s new IPU, “That’s not farming.” Others voiced concerns and misgivings to me, but few felt able to disrupt relations within the farming community and go on the record against other farmers.

While each planning application was different, there were a number of concerns consistently voiced by objectors. These were the foul smell, the visual impact of the IPU on the landscape, noise from the units and from the associated HGV traffic, road safety concerns, water pollution affecting local rivers, biodiversity loss from ammonia and that the proliferating industrial buildings would damage the local tourism industry, which was economically much more valuable to the economy of the area than agriculture.

One issue which tended to creep up on objectors as they researched the impacts of IPUs was the uncertainty over health impacts – the ammonia and dangerous particulates in the air, which can cause serious respiratory problems, the potential for spread of livestock-related infections, whether antimicrobial resistance, of which intensive animal farms are a major source, could linger in the local environment and the existential threat of a bird flu outbreak which might cross the species barrier. This particular concern has hardly lessened in the last year.

And yes, people were also concerned about whether a large IPU built near their house might affect the value of their property or deter future business customers. Others were vociferous about animal welfare issues or the evils of importing soya from South America for the bird feed. But overall I found that most people had multiple concerns – for themselves, their family, their health and their finances but also for the community, other people, local businesses, plus concerns about farming systems, planning procedures, democracy and justice.

Clearly there are extremely polarised values and concerns involved in these arguments. Planning officers and committees have difficult decisions to make, particularly as there are almost no planning policies that govern where intensive livestock operations can be sited. There is a policy void. The repercussions of allowing intensive poultry units to proliferate have been ignored in favour of facilitating the expansion of agribusiness.

Local plans for both counties have almost no reference to poultry businesses despite the numbers of sheds now nearing 1,150 and the number of birds in the counties at any one time approaching 38 million in my estimate. I found that the local authorities had neglected (intentionally or not) to develop supplementary planning guidance which would have clarified the situation for everyone.

Decisions were therefore made largely with reference to vague objectives in national planning policy such as “sustainable development” and boosting rural economies, and over 95 per cent of applications between 2000 and 2020 were given permission. I found that the planning committees have been dominated by local politicians who are embedded in local agricultural networks and tend to accept the farming lobby’s arguments or be cowed by the dominance of major economic actors such as Cargill.

The application the group I followed were fighting, like most others, was approved. But the campaigners did not give up. There is no third party right of appeal in the UK so they could not challenge the decision directly, but they applied for, and secured, a judicial review of the decision-making process. At this point the county council ceded the case, accepting that they had made errors when assessing some of the likely impacts of the IPU. This has happened in several cases now. Local communities have lost trust in the planning system and local authorities’ ability to make sound decisions.

Chicken is viewed as a healthy and convenient source of protein, but there are other more sustainable, cheaper and healthier protein options which could also be grown in the UK

Ultimately, Cargill (now a joint venture renamed Avara) succeeded in having its 90 additional sheds built, although it took much longer than anticipated and there were many battles along the way. In the process, local awareness about the range of cumulative negative impacts has been raised. In Herefordshire, the increased nutrient pollution and algal blooms in the rivers Wye and Lugg has finally woken up the council to the links with vastly increased amounts of poultry manure being spread on agricultural land.

In Shropshire, concerns over ammonia pollution of protected habitats now mean recent applications for IPUs must include technical fixes, such as expensive ammonia scrubbers. There is a better understanding of how local people, communities, environments and tax payers are paying the true costs of the externalities from the poultry industry, which avoids picking up the bill.

The situation also raises broader questions such as whether intensive livestock operations should be treated in planning law as agriculture or industry. The scale, intensity and impacts have changed dramatically since the last relevant planning act in 1990. One councillor told me: “If these sheds were producing spring coils they wouldn’t be allowed. They’d be encouraged to go to enterprise zones and business parks, but because this is, in policy terms, deemed to be agriculture, that’s a real problem.”

What this all brings home is the wildly unnatural price of chicken in the UK. Why can you buy a whole chicken at Tesco for under £3? The actual, but largely hidden, costs associated with the production of cheap chicken are not passed on to consumers. Neither are they paid by the owners of multinational meat processing conglomerates, Tesco shareholders or poultry farmers.

The costs are being paid by local communities and environments in the damage to the landscape, air and water pollution and quality of life. They are also being paid by the taxpayer, in terms of health costs or pollution clean-up costs, or renewable energy subsidy costs.

Chicken is viewed as a healthy and convenient source of protein, but there are other more sustainable, cheaper and healthier protein options which could also be grown in the UK. These include peas, beans, nuts and lentils, some of which have the advantage of fixing nitrogen in the soil rather than increasing nutrients in the environment. People could substitute such plant-based protein for chicken in many meals.

Read More:

So don’t wince when you see the price of chickens raised in better conditions – there are many reasons it’s more expensive and it’s not just the better environment the animals experience. You’ll be paying farmers who resist the dominance of multinational agri-industry and who are inflicting less harm on rural communities and localities.

Alison Caffyn is a research affiliate in geography and planning at Cardiff University. This article first appeared on The Conversation.

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments