The scientists hoping to make a breakthrough in carbon capture

Engineers at a Saudi university are working on a ground-breaking technology they hope can cut emissions

Researchers at King Abdullah University of Science and Technology are working on projects to offset carbon emissions and steer Saudi Arabia away from its dependence on oil.

Initiatives launched at the university - in line with the country’s Saudi Green Initiative - include Red Sea Farms, where sea water is used to grow crops and cool down greenhouses. It is also partnering with NEOM to build the world’s largest coral reef garden on Shusha Island.

Other areas of focus include AI, smart health, cybersecurity, and climate change. Professor Tony Chan, the university’s president, believes its strength is that it does not follow the traditional structures found in higher education. “We are not split into departments, because we live in an era with overlapping concerns,” he says. “It’s important that we work not in silos but in collaboration.”

I was invited to discover this first-hand, meeting with Professor Ibrahim Hoteit, whose findings on the Red Sea show how it was impacted by the climate crisis – and what can be done to restore balance in the ecosystem.

There was a whiff of rebellion in the air on campus – something rare in Saudi Arabia – and a hunger to find new solutions to the climate crisis. Working in a country that is one of the world’s worst carbon emitters, scientists here feel an incentive to help fix past damage.

But is there a way of reducing Saudi Arabia’s carbon footprint without shuttering operations on which millions of lives depend? More specifically: is there an effective way of capturing the carbon that gets pumped into the atmosphere – to recycle and to use as an alternative energy source?

Currently there are three main ways to do it – but they are expensive and energy intensive.

Carbon can be captured before burning fossil fuels, after burning them, or via oxyfuel. The first method consists of converting the fuel into a mixture of CO2 and hydrogen. The second consists in removing the CO2 from the flue gases emitted during combustion. The third method burns fossil fuels with almost pure oxygen instead of air.

Today’s technology can capture up to 90 per cent of CO2 emissions and convert them into power sources. Large industrial installations have championed this because it allows them to offset their footprint.

Researchers are now investigating ways to make carbon capture cheaper in the hope of it being adopted more widely. Specifically, they are working on cryogenic carbon capture (CCC), which isolates the carbon from the flue gases by freezing it.

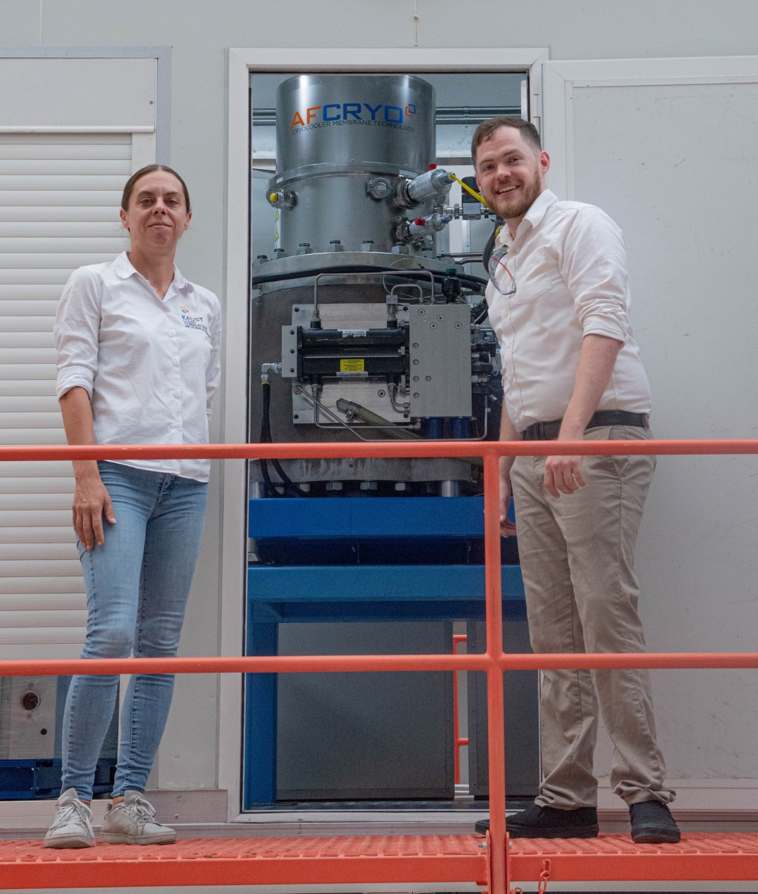

Among the team looking into the new technology is Chris Wagstaff, a PhD student, who is working with his fellow engineers on what they hope could be a revolutionary machine. He was an undergraduate at Utah when the idea of CCC was first floated by senior professors there. Wagstaff was sceptical at the start, but eventually curiosity got the better of him.

He drove me round to the engineering lab where the first models of their machine are being built and tested. “What we’re assembling here is a machine that requires no steam and no external energy to operate,” he explained.

This is to undersell what’s being attempted: KAUST are building a technology that could, if things go to plan, make carbon capture self-sustaining. The classic cryogenic carbon capture machine relies on energy to heat up the frozen carbon and convert it into liquid, as required for storage and conversion into a power source. The KAUST engine, by contrast, is built to be autonomous and derive energy from itself.

The same heat exchanger processes dual functions: it refrigerates and solidifies the carbon to separate it from the gas, and then heats it up again to make it liquid. This constant cycle of activity is self-regenerating; heating is powered by refrigeration, and so on.

This cutting-edge machine is still in its developmental stage, but, researchers believe, holds out the prosepct that CCC could become the default choice for big carbon emitters.

They were cautious of sharing too many details about the next steps: “We’re still trying things out,” Wagstaff said. Small scale trials are now being run with the hope that industrial scale deployment won’t be too far behind.

Alongside those trials are further experiments. Indeed, there are multiple benefits to CCC, including the removal of pollutants such as nitrogen oxides and mercury. The team at KAUST is currently exploring how their machine might also distil and recycle sulphur dioxide, a toxic gas, of which Saudi Arabia is one of the world’s highest emitters.

Bookmark popover

Removed from bookmarks