How to fix India's burning issue: turn unwanted straw into bioenergy pellets

The practice is causing havoc on India’s roads and exacerbating health problems, but alternative ways of getting rid of it have long been beyond the reach of most farmers’ pockets

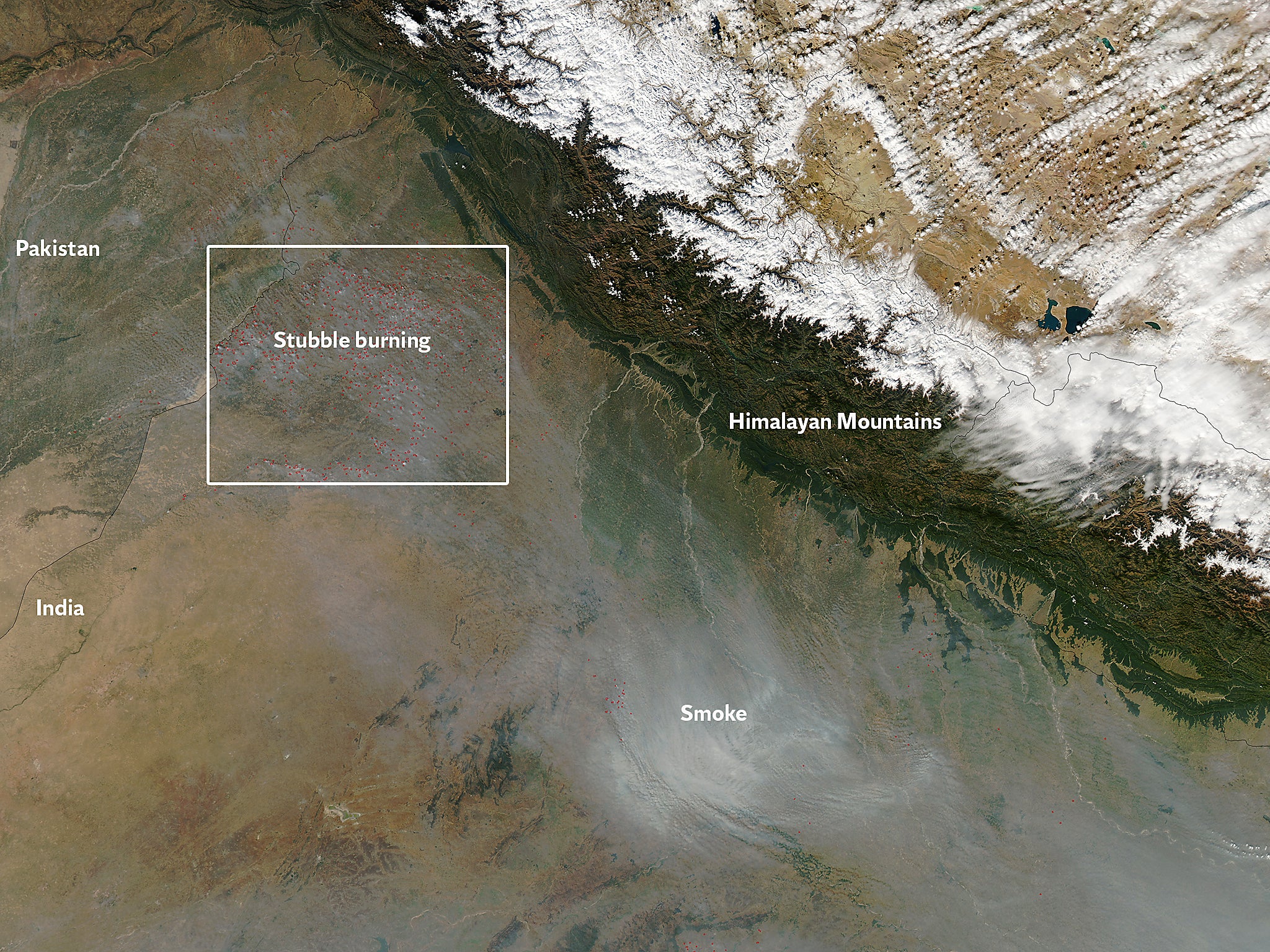

Each year, fires rage across northern India, as farmers burn off their unwanted straw. The impact is enormous. From October into November, massive clouds of smoke streak across Punjab and neighbouring states, blown by the prevailing winds in the direction of Delhi.

Every year, ministers demand action – in 2016, they were joined by India’s Supreme Court. And every year, Nasa publishes new satellite photos showing the extent of the burning. People die on the roads as the smoke limits visibility, while heart and lung problems are exacerbated.

The fertile fields of Punjab produce about 20 per cent of India’s rice and 40 per cent of its wheat. Rice is grown from May to October, followed in the same fields by wheat from November to March. The turnaround between rice harvest and wheat planting must be quick, as any delay badly affects wheat yields.

The 11 million tonnes of rice grown in Punjab leaves behind about 21 million tonnes of straw – the inedible part of the plant. Farmers typically have just 20 days to clear it away before the wheat season begins. The straw is usually burned openly in the same fields where it was grown, in spite of regulations and knowledge of environmental and human damages.

This has been part of Punjabi culture for decades (neighbouring Haryana and Western Uttar-Pradesh follow the same crop cycle in comparable quantities). India is not unique – the state of California burnt residue as recently as the 1980s and straw burning continues in many parts of Southeast Asia and Africa today.

Burning is doubly wasteful as the straw is lost to the flames. Each year, the soil loses more carbon, nitrogen and other nutrients. Every acre of paddy yields approximately 2.5 tonnes of straw. Burning that straw sends approximately a tonne of organic carbon into the atmosphere (in the form of gases such as carbon dioxide, carbon monoxide and others) along with other nutrients such as nitrogen, phosphorus and potassium.

There are lots of alternatives to burning, but all have their problems. Paddy straw isn’t nutritious enough to make good animal fodder, and its high concentrations of silica can damage traditional farming equipment.

As rice is typically grown in small fields, it also isn’t always possible (or affordable) to use the high-powered machinery necessary to till the straw deep into the soil prior to planting wheat. Other solutions like using straw for biomass power or to make paper all require lots of new infrastructure.

Straw is already collected and baled today in a few of Punjab’s large farms, and other areas near biomass power plants. But baled straw is difficult to handle, and bulky to transport and store. Expensive power plants often sit idle for weeks, surrounded by fields of damp straw that cannot be used until dry.

Straw burning is illegal but, as the alternatives are either impractical or expensive, most farmers still do it. They’re making a rational decision. Therefore, irrespective of government policy and wider environmental considerations, any solution must give farmers themselves a good incentive not to burn.

To resolve some of these problems, we have developed EnergyHarvest. First, paddy straw is compressed into small pellets using technology normally used to produce animal feed. An oxygen-free heating process known as pyrolysis then converts these pellets into energy outputs: heat and “biochar”, a form of charcoal.

These pellets transform paddy straw into something useful. Each pellet contains lots of energy for its size and weight. They’re easy to handle and store, and less expensive to transport than big bales of straw.

The biochar that the pellets are turned into after pyrolysis captures most of the carbon and nutrients present in the original straw. When returned to the ground it makes the soil healthier and retain more water.

Meanwhile the heat given off during pyrolysis can be captured and used to produce hot water, or mechanical or electrical energy. It could also be converted into refrigeration for food at half the price of conventional electric cooling. It’s important that these pellets can be used in lots of different ways because different farming areas will present unique requirements and opportunities.

We’ve set up a demonstration of the EnergyHarvest technology at the Punjab Agricultural University (PAU) and a series of three-year randomised field trials are under way. The cooling is integrated with the cold-storage demonstration systems at PAU’s food science department.

Our work on converting straw into pellets, and processing these pellets into useful products, won’t solve open field burning – or Delhi’s air pollution – overnight. But it does mean that small-scale farmers, the majority of farmers in Punjab, can now do something useful with their leftovers.

This article first appeared on The Conversation (theconversation.com). Robert Berry is a professor of computer science and Sudhakar Sagi is a researcher in chemical engineering at Aston University. MS Mavi and OP Choudhary from the Department of Soil Science at Punjab Agricultural University also contributed to this article

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments

Bookmark popover

Removed from bookmarks