Scientists find key to fat-free cream in beer and plants

Other dairy-free creams typically contain at least 25 per cent fat, are complicated to produce, and are filled with E-number food additives

Your support helps us to tell the story

From reproductive rights to climate change to Big Tech, The Independent is on the ground when the story is developing. Whether it's investigating the financials of Elon Musk's pro-Trump PAC or producing our latest documentary, 'The A Word', which shines a light on the American women fighting for reproductive rights, we know how important it is to parse out the facts from the messaging.

At such a critical moment in US history, we need reporters on the ground. Your donation allows us to keep sending journalists to speak to both sides of the story.

The Independent is trusted by Americans across the entire political spectrum. And unlike many other quality news outlets, we choose not to lock Americans out of our reporting and analysis with paywalls. We believe quality journalism should be available to everyone, paid for by those who can afford it.

Your support makes all the difference.The ‘dieter’s dream’ of fat-free whipped cream has been made from beer and plants, according to a new study.

University of Copenhagen researchers have replaced milk fat with bacteria to create a prototype fat-free, sustainable whipped cream.

At present regular whipped cream contains 38 per cent saturated fat, required to provide the airy and stiff consistency.

To create an alternative, the team successfully built on their work of using lactic acid bacteria to form tiny building blocks to create food.

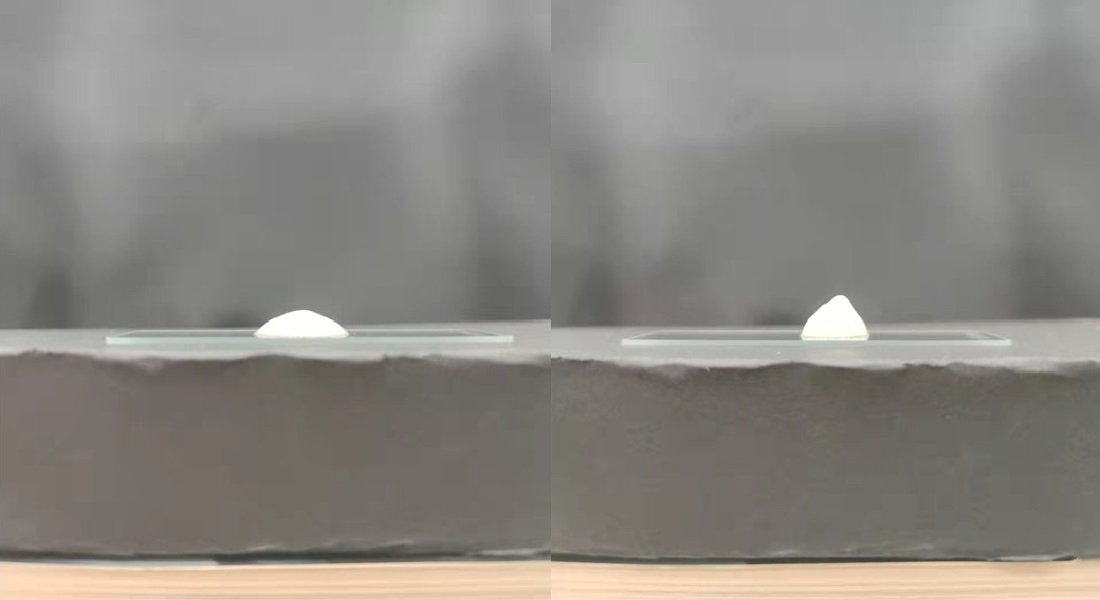

They managed to produce both fluffy and stiff versions of the cream.

Lactic acid bacteria are everywhere, inhabiting human and animal mucous membranes and digestive tracts, and plants, and commonly used to create culture yogurt and preserve cold cuts.

Though there are a number of dairy-free whipped creams on the market, they are created using saturated sources of fat imported from tropical regions, such as coconut and palm fat.

Moreover, they contain at least 25 per cent fat, are complicated to produce, and are filled with E-number food additives.

Associate Professor Jens Risbo of the Department of Food Science said: “The most difficult aspect of developing an alternative food is getting the texture right.

“Whipped cream undergoes a unique transformation that occurs in a complex system where a high saturated fat content makes it possible to whip the cream stiff.

“So, how do we create an alternative where we avoid the high fat content, while still achieving the right consistency? This is where we need to think innovatively.

“We usually associate bacteria with something to keep away from food. But here, we base a beloved food product on good bacteria found in nature.

“This has never been seen before. This is advantageous, both because it is a renewable resource grown in a tank, and because it creates a healthier, less energy dense, fat-free product.

“Here we only use four ingredients – water, bacteria, a bit of milk protein and a single thickener. With these few ingredients, we’ve managed to make a fat-free product that can be whipped, peaks up and retains the liquid.”

The fat content is so high because fat globules in cream clump up as they’re whipped to create the airy foam.

The foam then stabilises to provide the necessary strength to keep it standing up, without the liquid draining out.

Researchers used two different lactic acid bacteria for the fluffy and stiff creams, both roughly the same size as the fat globules in dairy-based whipped cream.

One bacteria has a water-like surface which forms a weaker network and produces a softer foam.

The second is closer to fat, forming stronger networks and a stiffer foam capable of standing in tall peaks.

Professor Risbo noted their invention is not yet a stand-alone product, rather an insight into how foods can be created without dairy.

He added: “We’ve shown that bacteria can be used to create the right structure. Now that we understand the context and have learned which surface properties are important, it opens up the possibility of using many other things from nature.

“This could be yeast residue from brewing, or perhaps small building blocks that we extract from plants.

“This would make the product very sustainable.”

The findings were published in the journal Food Hydrocolloids.

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments