Recycled products shatter old ideas about ceramic waste

THE ARTICLES ON THESE PAGES ARE PRODUCED BY CHINA DAILY, WHICH TAKES SOLE RESPONSIBILITY FOR THE CONTENTS

Every two months, Yan Chunyang hauls the accumulated ceramic waste from his studio to two large green bins, which serve as designated recycling points for ceramics.

“It has been about two years since I started taking ceramic waste to the recycling point. Many other studio owners in Jingdezhen also go there to dispose of their waste ceramics,” he said.

Yan is a 33-year-old freelance artist who set up his ceramic 3D-printing studio in Jiangxi province’s Jingdezhen, the country’s porcelain capital, in October 2021.

He quickly became a vendor at the Letian Pottery Creative Market, showcasing and selling his products every Saturday along with other vendors.

China has been the world’s main producer of traditional ceramics for many years.

In 2017, China produced approximately 107 billion square feet of architectural ceramics, 220 million pieces of sanitary ceramics, and 50 billion pieces of daily-use ceramics, according to research by Wang Yongqing, a professor at Jingdezhen Ceramic School of Materials Science and Engineering.

The central region accounted for 25 per cent, 55 per cent, and 45 per cent of these outputs respectively, while Jiangxi was the third-ranked province in traditional ceramic production.

However, the thriving ceramic industry has created a problem: How to deal with the large amount of non-degradable ceramic waste produced by manufacturing companies?

Jingdezhen alone produces more than 60,000 metric tonnes of ceramic waste annually, with an estimated 18 million tonnes produced nationwide.

“There are many types of ceramic waste, not just traditional daily-use ceramics, but also architectural ceramics, sanitary ceramics and more,” said Wang. “Currently, some ceramic waste is recycled, but many companies still resort to traditional landfilling.

“Ceramics are not degradable, and burying them takes up a lot of land. Moreover, some glazed ceramics waste may contain harmful chemicals that can be released over time, posing a threat to the environment.”

Ceramic waste disposal can also pollute the air and contaminate groundwater quality, he added.

Oceano, a tile manufacturer with factories in Jingdezhen and Foshan, Guangdong, has been researching ways to recycle and utilise ceramics for a couple of years.

“At present, we have established a green recycling system in our factories, and most of the waste generated during production can be recycled internally for use as new building materials,” said Rong Liang, deputy general manager of Oceano in Jingdezhen.

At its Jingdezhen factory, Oceano’s annual output of ceramic building materials is about 237 million square feet, with a recycled ceramic reuse volume of about 40,000 tonnes.

In Foshan, the amount is about 53.8 million square feet, with a recycled ceramic reuse volume of about 10,000 tonnes.

The recycling project at the Letian Pottery Creative Market was initiated in 2021 by Yi Design, a Chinese materials company, and the Letian Pottery Workshop.

Caroline Cheng Yi, the founder of the workshop and one of the co-founders of Yi Design, has been advocating sustainable recycling of ceramic waste for a long time.

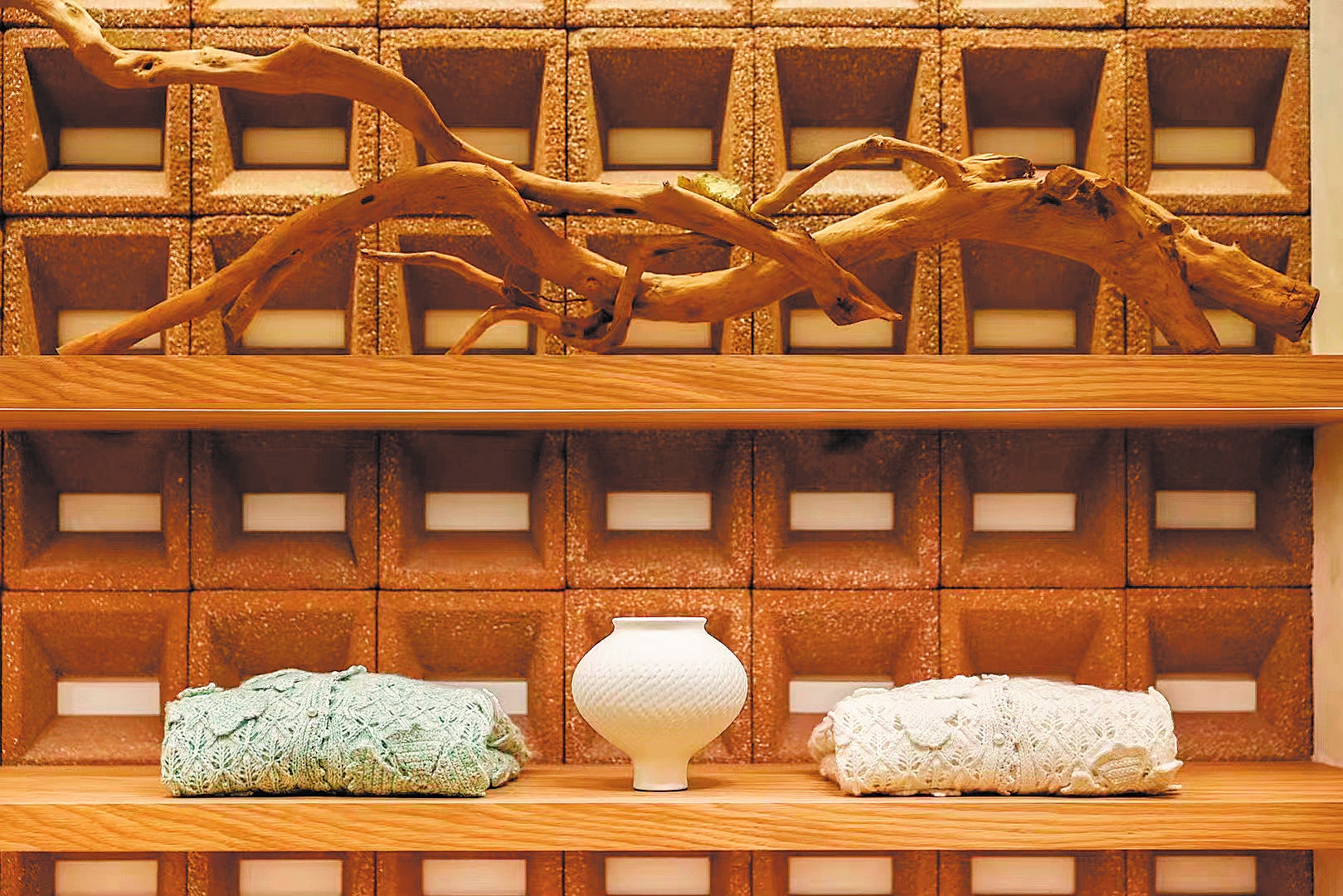

Over the past three years, Yi Design has developed four types of recycled tiles and bricks.

“Our lab focuses on researching ceramic waste and solid waste as primary raw building materials, with an emphasis on art and aesthetics, to develop sustainable and environmentally friendly materials and products for the construction and design sectors,” said Deng Peiran, head of the company’s design department.

Yin Yi, one of the co-founders of Yi Design, said that building blocks the company has made from ceramic waste can be used as an “absorbent alternative” to conventional cement bricks in various situations.

Yin’s interest in ceramic waste recycling began in 2018 when he decided to do a master’s degree on future materials at Central Saint Martins in the United Kingdom.

Yin said their next step is to reduce costs and explore the possibility of increasing mass production of their materials.

“In the future, we hope to achieve large-scale production and help realise the green development and transformation of the ceramic industry,” Yin said.

Bookmark popover

Removed from bookmarks